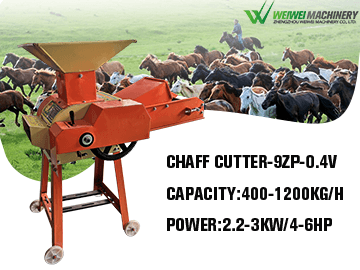

The first advantage: save farming costs, save floor space, save time and effort, and one person can feed a whole farm. It is known that pellet feed can increase the stack density by 40% to 100%.

The second advantage: avoiding a single nutritional feed material, promoting the conversion of starch in feed with a sweet taste, increasing livestock and poultry intake and reducing slaughter time for livestock and poultry.

The third advantage: the pellet feed form makes the livestock and poultry digest the feed for a longer period of time and also increases the digestibility of the livestock and poultry, thus facilitating the absorption of nutrients.

The fourth advantage: feed pellet machines process pellet feed generally at around 70 degrees. The high temperature kills some pathogens and helps livestock and poultry to resist the spread of disease.

The fifth major advantage: the pellet feed made by the feed pellet mill can be stored for a period of time and is not easily affected by moisture, which can effectively prevent the raw materials from growing mould and powder moisture control. After successful pelleting, it should be completely dry or cool. Feeding livestock with pellet feed increases the feed conversion rate by 15%, reduces the meat to feed ratio by 6% and increases the weight of livestock by 4% compared to powdered feed, which is probably why feed pellet mills are more popular today.